Update on the watchcase project.

In May, I started making a small tin watch case for a friend. He had sent me some photos of a similar watch case he had found in an antique shop and wanted me to make him a similar one. You can read that post here.

Since then I have had requests for more cases and have three on the bench now. I thought I would go back and discuss some of the details of the construction of this sort of project. I do not have much experience making tin boxes, so there has been a fair amount of learning.

It should be noted right up front that I believe that making square stuff is more difficult than making round stuff. For example, when I make a round tin lantern, if the cone is a touch too big or too small, I can tweak the diameter of the body a bit to even things out. But if you mess up square parts, they are just wrong and usually scrap.

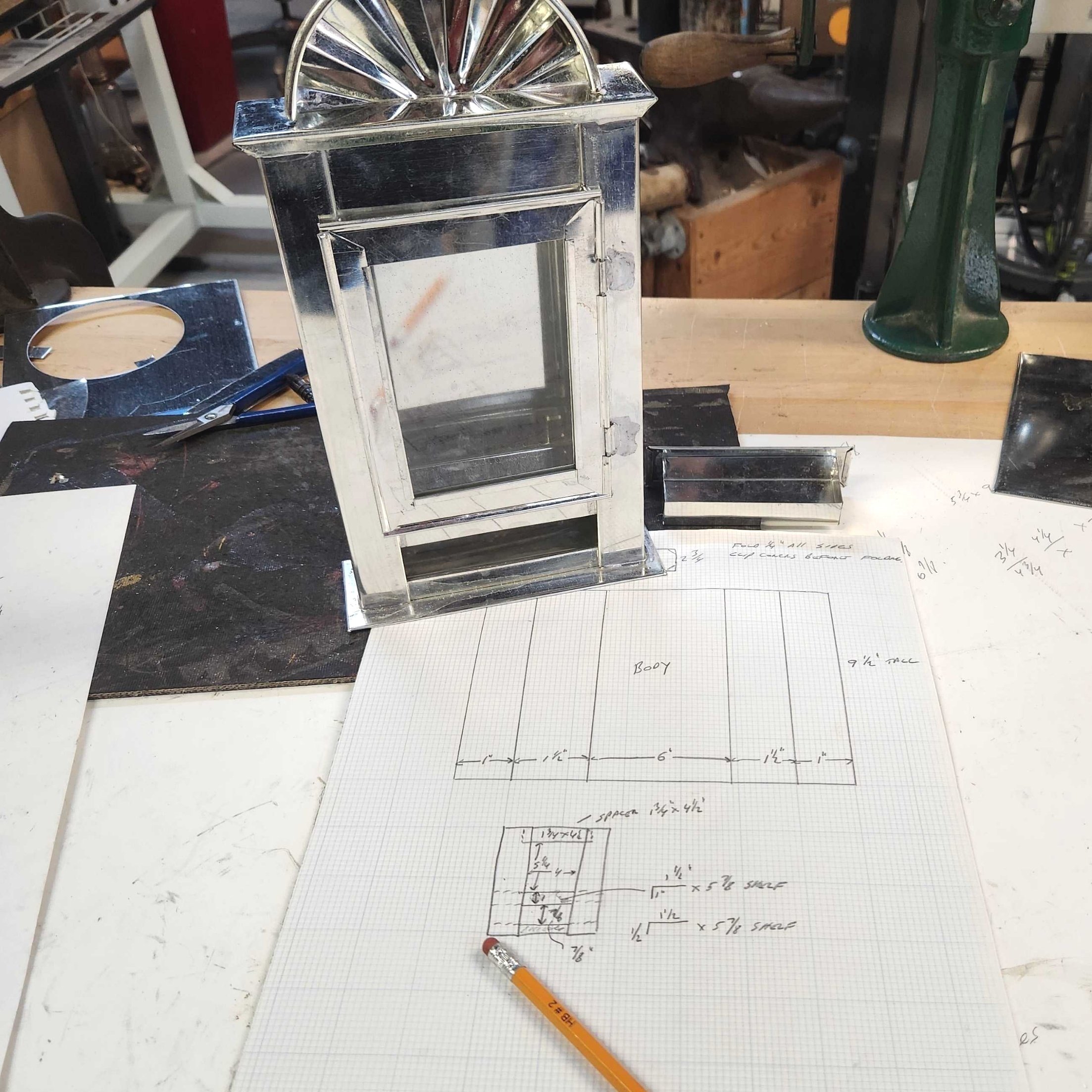

Over a period of several shop sessions the design comes together. Here is a photo of one of the early attempts that came together decent. About the most difficult things I ran into was soldering the several flat unsupported edges together. If you add to much heat the metal expands and warps, making it impossible to get a good solder joint. Parts with folded edges or short seams are much easier to solder.

For most new designs I try to draw up a basic CAD drawing to get the basic dimensions and proportions worked out. This never turns out to be the final design, but it helps me visualize the basic components and helps me get started.

The part of this project I was most apprehensive about was making the scalloped top with the wired edge. It turns out to just be a series of front and back folds done on my square pan swedge. I ended up making several different-sized semicircles until I found the one that worked best for this size of case. The antique case looked like it was more of an oval shape. Maybe I will try to figure that out next time.

In the end I think the case came out nicely. The antique finish and weathered glass sets off the watch case and makes the watch look really good.

The next set of these is underway and I will be posting photos on my Facebook and Instagram sites soon.